The heat exchanger is designed for the industry's maximum efficiency. The combined surface area of the heat exchanger plates is 26,000 square feet, larger than five professional basketball courts, and tiny ripples on each plate increase the heat transfer area.

Greater Water Efficiency

More effective dry heat transfer than polymeric heat exchangers. Up to 85% effectiveness in dry mode longer, thereby reducing water consumption and associated water treatment costs.

Highest Energy Efficiency

- Performs efficiently in both dry and wet operating modes

- Cooling to within 1 degree of wet bulb temperature

- Up to 85% effective heat transfer in dry mode

- Air leakage of less than 0.1%

- Peack mechanical PUE of less than 1.25 and annualized PUE of 1.10

Lowest Air Leakage

The Liebert EFC heat exchanger has the lowest air leakage in the industry - just 0.1%. Excessive air volume leakage and displacement in heat wheels and other competitive systems can lead to unit oversizing to make up for the loss of air. This leads to higher capital costs and more power being consumed by cooling instead of being available to support revenue generating IT loads.

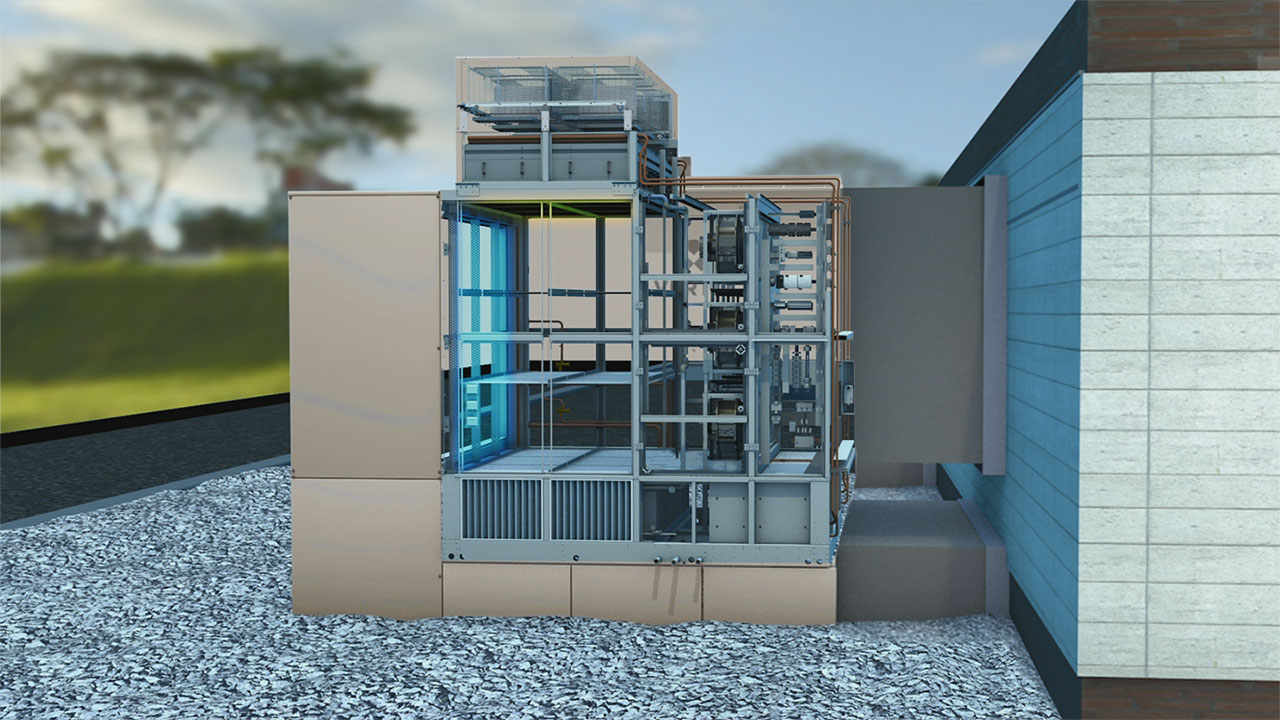

The heart of the EFC system is its epoxy-coated, aluminum heat exchanger, the most efficient and durable heat exchanger ever built for use in data centers.